Environment

Materials

Mineral wool or elastomeric insulation? - Saint-Gobain has both

Maritime environment demands a lot from insulation materials. For example, during an intercontinental crossing, they have to withstand both icy temperatures in Nordic waters and tropical climates within a very short time – without losing their insulating potency.

In addition, fire protection upon the seas is of great importance due to the sometimes limited possibilities and long delays in rescuing people. Against this background, it’s no surprise that when a cruise ship is insulated, this can require up to 500,000 square metres of insulation.

As an industry leader, Saint-Gobain has frequently drawn attention to the significance of effective and sustainable insulation in Marine & Offshore. Saint-Gobain’s biggest hit product at the shipyards of late has been ISOVER ULTIMATE mineral wool which is produced through a unique and patented fiberizing process.

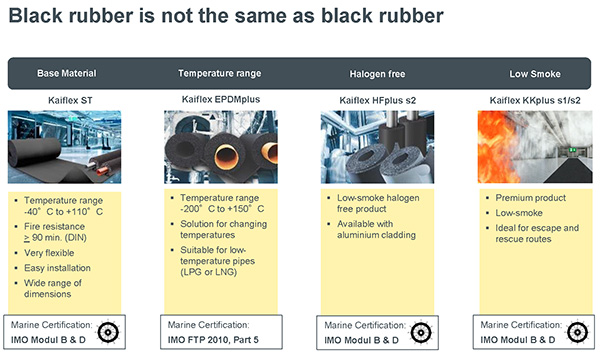

However, as Saint-Gobain purchased Kaimann, one of Europe’s leading manufacturers of elastomeric insulation products in 2018, the company’s portfolio added some of the best flexible rubber insulation materials in the world.

Elastomeric edge

Key Account Manager Herkko Miettinen from Saint-Gobain remarks that mineral wool and elastomeric are similar in the sense that they offer first class insulation properties and energy savings.

“Elastomeric insulation prevents condensation very well and that’s why it’s in high demand in cruisers that naturally feature many cooling systems,” Miettinen says, adding that another target group for elastomeric is LNG vessels, due to condensation management challenges as well.

According to Miettinen, as designers get to work on big projects such as a cruise ship, there are areas where mineral wool is a better fit – and areas where elastomeric products will do the trick.

“Planners have a very good handle on the application range and we offer support to find the best product in each case.”

Energy matters

Energy consumption related to HVAC (Heating Ventilation and Air Conditioning) systems constitutes a large part of the total fuel consumption of a ship, up to 35 % on a cruise ship. Having high thermal insulation in the decks, bulkheads and ducts can have a significant impact on operating costs – and this is why major shipyards are eager to engage in close collaboration with Saint-Gobain.

“Our solutions are supplied to the big shipyards across the world, ranging from Meyer Turku to other key European shipyards,” Miettinen says.

Collaboration is going strong even amidst the pandemic: Miettinen reports that shipyard challenges – such as lack of components – have been overcome, for the most part.

“Cruise ship industry is in pretty good form and so is the marine sector in general.”

More information:

Saint-Gobain Marine

Kaimann ship building

KaiCalc online calculator

Text by: Sami J. Anteroinen

Photos by: Saint-Gobain Finland